LEMAIRE AT THE EMO FACTORY

For several collections, LEMAIRE has been conceiving a series of second skin garments made from fine fabric with a delicate, slightly transparent texture. To produce these pieces, LEMAIRE has called on the savoir-faire of EMO.

This Troyes-based company has been specializing in the manufacture of tubular knitwear for over forty years. Based in Aube, EMO took over from the Mauchauffé hosiery, one of the region's many family run factories, founded in 1876. Mauchauffé, which brought together the four main stages of production on the same site: mechanical engineering, knitting, dyeing and garment making, obtained numerous patents (rewarding innovation rectilinear and circular sewing looms) before becoming the largest hosiery factory in Europe at the beginning of the 20th century.

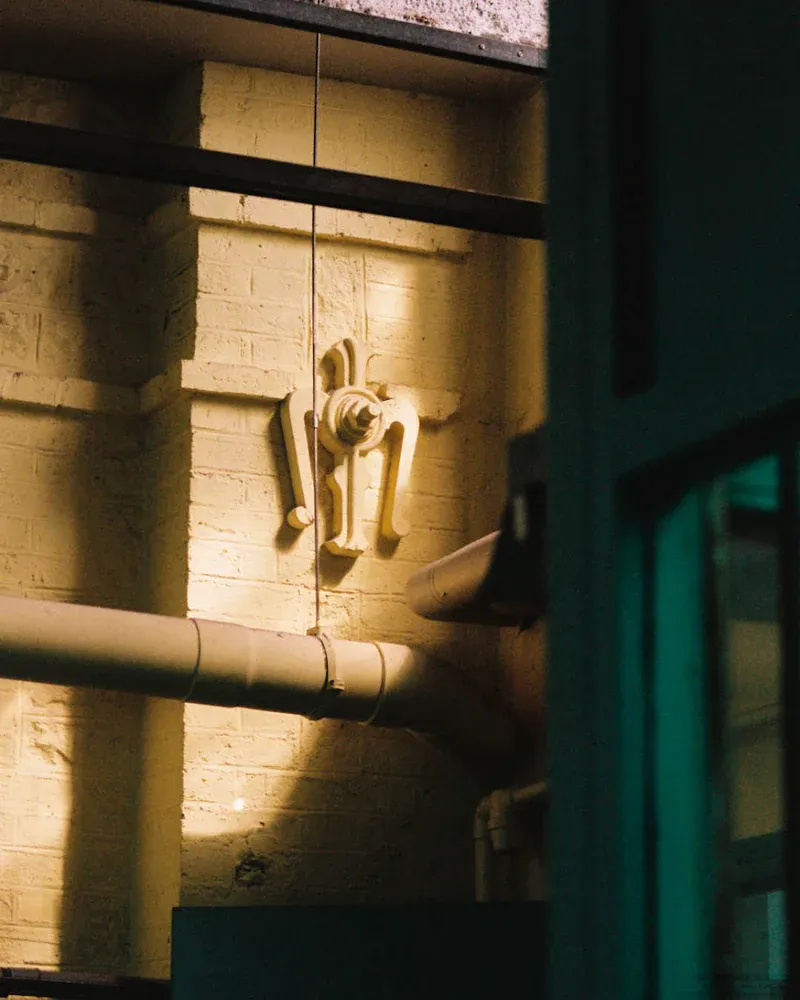

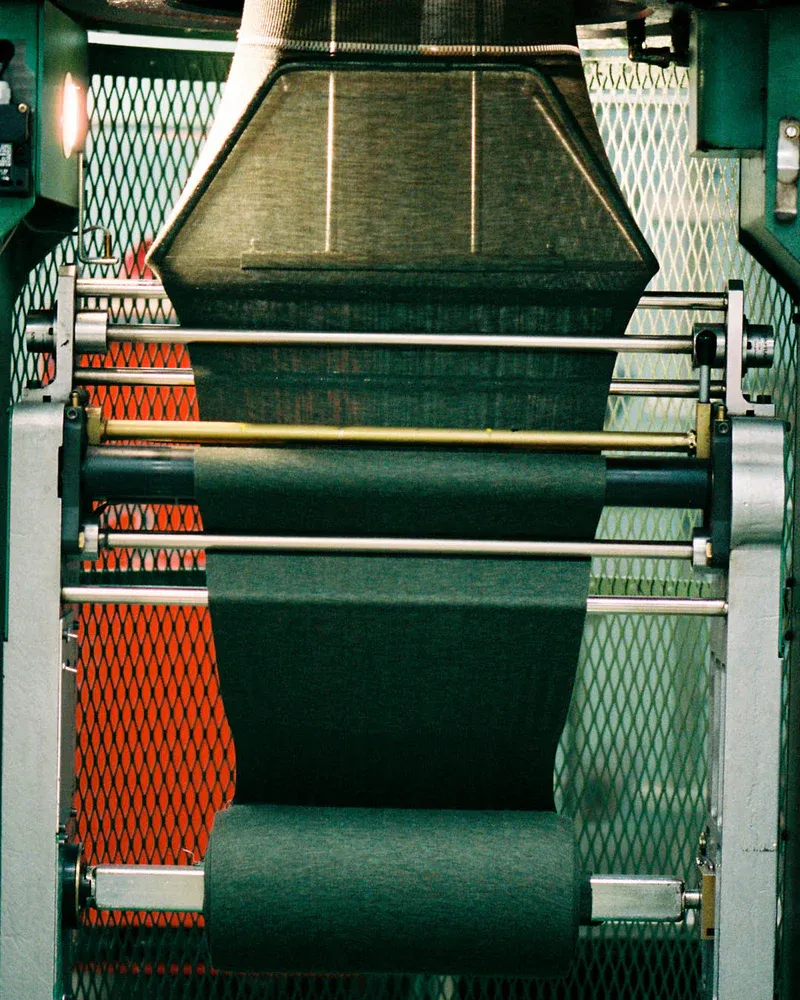

In 1978, 120 of the company's employees decided to take over the EMO brand, then associated with luxury goods within Mauchauffé. Today, EMO’s workshop is home to an impressive array of circular knitting machines, which make it possible to produce garments without side seams.

THE CIRCULAR KNITTING MACHINES PRODUCES SQUARES OF FABRIC WITHOUT SIDE SEAMS

A PROTOTYPING PHASE LEADS TO THE CREATION OF PATTERNS BASED ON ORDERS

THE PANELS ARE STACKED AND QUILTED ON NEEDLE TABLES

THEN CUT TO SIZE BY A BAND SAW FOLLOWING THE PATTERNS

THE PANELS ARE PRESSED ONE LAST TIME

THEN IT’S TIME TO MANUFACTURE THE PIECES USING OVERLOCKERS, STITCHERS AND BUTTONHOLES

EACH PIECE IS CHECKED DURING « RACCOUTRAGE » AND DARNED IF NECESSARY

THE GARMENT IS THEN FOLDED AT THE PACKAGING DEPARTMENT AND READY TO GO